oxygen molecular sieve,wildly used in PSA/VPSA system.like medical/industrial oxygen generator in 1–5L family oxygen concentrator,fish farming,hospital and so on.Oxygen molecular sieve has the advantage of high N2 adsorption capacity, High N2 and O2 seperation efficiency,high purity 93%+/–3% having good reputation in market.

Details information as belows

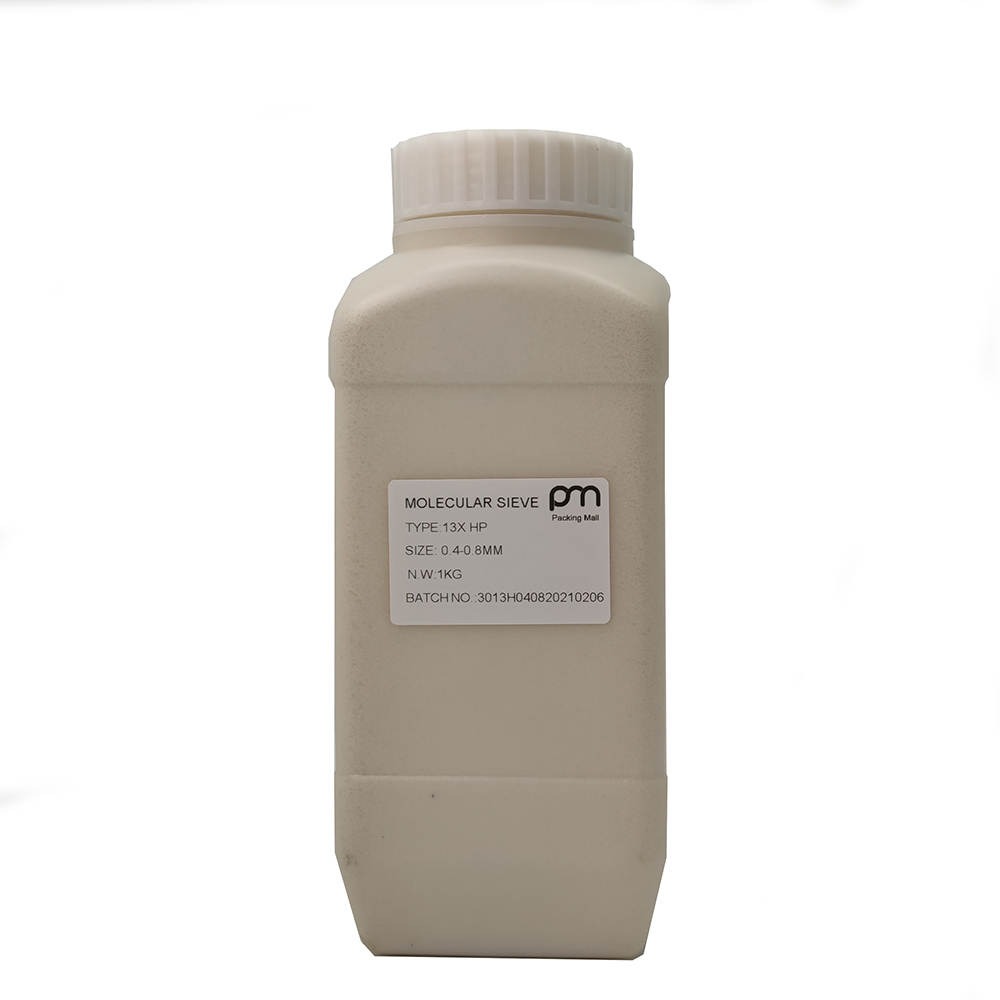

OXYGEN MOLECULAR SIEVE

There is no decisive role for consumers to choose an oxygen extraction rate. The data of molecular sieve procurement and production used by each manufacturer are not disclosed. It can only be what people advertise.

If it were not the purchasing and project manager of the oxygen maker, the people working in the factory would not know what molecular sieve was used.

The decision to write this article is to force myself to study, and can also help the medical device peers in the industry. Many people may also want to know, but no one writes about them.

- First review the basic knowledge

Molecular sieve composition: It is a synthetic zeolite material with precise and uniform structure and pore size. This allows them to preferentially adsorb gases and liquids based on molecular size and polarity.

Zeolites are naturally occurring, highly porous crystalline solids and belong to a chemical category called aluminosilicates.

There are four main types of molecular sieves: 3A, 4A, 5A and 13X. The type depends on the chemical formula of the molecule, which determines the pore size of the molecular sieve.

The role of molecular sieve: The working principle of molecular sieve is to adsorb gas or liquid molecules smaller than the effective diameter of its pores, while excluding those molecules larger than the opening, which determines the efficiency and concentration of oxygen production.

- Well-known brands of molecular sieve at home and abroad

US/France:

- Honeywell International Corporation, USA

- American damlakimya (damlakimya), there are partners, British Weikang, Asia

- France Arkema China (arkema), partners include, Kaia and other domestic brands of oxygen generators

China:

- Shen Tan, Shanghai Shen Tan Environmental Protection New Material Co., Ltd.

- Mingmei, Anhui Mingmei Mineral Chemical Co., Ltd.

- Global, Shanghai Universal Molecular Sieve Co., Ltd.

- Xiang brand, Zhengzhou Tianxiang Inorganic Material Co., Ltd.

- Xianfeng, Nanjing Xianfeng Nano Material Technology Co., Ltd.

- Top, Shanghai Top Molecular Sieve Co., Ltd.

- Naco, Langfang Naco New Material Technology Co., Ltd.

- World Expo, Guangde World Expo Synthetic Carbon Material Co., Ltd. (Anhui)

- Jianlong Weina, Luoyang Jianlong Weina New Materials Co., Ltd.

- Saili, Wuxi Saili Molecular Sieve Co., Ltd.

In general, molecular sieves at home and abroad will be good or bad, and the grade is not necessarily that imports are good. Common molecular sieves are also imported.

In the same way, domestic molecular sieves are not necessarily bad. It is better to choose molecular sieves with higher grades than imported ones.

Therefore, we should not blindly pursue the so-called import is good thinking, we should actually look at the quality of the product.

- Details of molecular sieve for oxygen generator in China

At present, most of the oxygen generators on the market use domestic molecular sieves, but why do they promote the use of imported molecular sieves?

Because the molecular sieves are mixed, as long as the structure and size of domestic and imported molecular sieves are the same, even if 10% of the imported molecular sieves are used, the imported molecular sieves can be promoted to the outside world.

From the point of view of supervision, it belongs to the sideline ball, and it is also a manifestation of the profound and profound Chinese writing.

Therefore, when you choose an oxygen generator, try to choose a brand with a long machine life, stable oxygen concentration, and low after-sales rate.

Time is often the best proof, saving money is small, delaying the condition is big, hospitalization after the critical condition deteriorates, you think the patient is too weak, in fact, it is likely that the patient is inhaling invalid oxygen.

- How to judge the molecular sieve of an oxygen maker

Before selecting the machine, it cannot be judged.

Disassembling the machine to open the molecular sieve storage tank, it is not necessarily visible to the naked eye. Remember one of the characteristics of molecular sieve? Adsorbability is strong, which determines the efficiency and concentration of oxygen production. Only by testing under specific experimental conditions can data be obtained, and ordinary consumers can hardly detect it by themselves.

- What is the difference between French molecular sieve and American molecular sieve?

Imports are mainly French lithium-based molecular sieves and American sodium molecular sieves. Domestic-made molecular sieves generally use lithium-based molecular sieves.

The conversion efficiency of American sodium sieve is not as good as that of lithium sieve, with high humidity resistance and stability.

The French lithium sieve has a fast oxygen extraction rate and high adsorption efficiency, but it is susceptible to moisture.

The French lithium molecular sieve is commonly used on the market, so it is recommended that the oxygen generator should be kept ventilated and dry and be turned on regularly to avoid the molecular sieve being wet and causing the oxygen concentration to fall below the medical standard.

It is best to regularly use third-party testing equipment to test, the machine is not necessarily accurate.

Molecular sieve is just a raw material, and the core of determining oxygen concentration is filling technology.

How much the molecular sieve is filled and hermeticity determines the ability of continuous oxygen supply. If the filling technology is not tight and the friction is too large, it will cause moisture easily. After 1-2 years of machine use, the oxygen concentration drops rapidly.

For example, some machines of Nanpai manufacturers do not have a low oxygen concentration alarm function, which is difficult for ordinary consumers to find.

- Molecular sieve filling technology and mixing ratio are the core technologies

As mentioned earlier, the conversion efficiency of the American sodium sieve is not as good as that of the lithium sieve, and it has high moisture resistance and stability; the French lithium sieve has a fast oxygen output and high adsorption efficiency, but it is easy to get wet.

Each has its own advantages and disadvantages. Traditional manufacturers of oxygen generators will use a single ratio of sodium or lithium molecular sieve, which later became popular for mixing and filling.

The ratio of sodium to lithium used in each model has always been a trade secret within the manufacturer.

To save costs, some small domestic factories use manual filling of molecular sieves. Large factories now generally use computer-controlled equipment for filling. The relative manual advantages are better proportional control, fewer process defects, and good installation stability.

Purchasing equipment and molecular sieve mixing and filling technology are all invisible costs. Good equipment, naturally expensive, and stable oxygen output.

But many consumers often only see the purchase cost of materials, but not the hidden costs.

Summing up:

- Ordinary consumers cannot see whether the molecular sieve is good or bad.

- The molecular sieve is a precious accessory, and the machine is regularly turned on to help prevent the molecular sieve from being damp.

- Molecular sieve is just raw material, the core is the mixing ratio of the manufacturer’s molecular sieve lithium sodium molecular sieve, filling technology.

Reviews

There are no reviews yet.